The Power of Traceability: The Ultimate Shield Against Recall Risks

This blog discusses how manufacturing execution system benefits extend well beyond the realm of improved productivity and reduced waste, offering you a robust means to ensure traceability and, subsequently, compliance.

SMTA CALCE Counterfeit Material Symposium

At the upcoming CALCE UK 2023, Michael Ford of Aegis Software, Damian Glover of Wider.Team and Lubna Dajani of Allternet.com will be discussing how to achieve traceability throughout the supply-network without the need to necessarily change internal processes, domain-based traceability standards, existing solutions and existing data storage methodologies.

DPMX And The Digital Thread

Building your tree of knowledge, your Digital Thread, contextualized based on clear design information with IPC-2581 DPMX, should be one of the most important steps that you can take to ensure success in your Digital Transformation of manufacturing practices. This blog post discusses why design data, in the form of IPC-2581 DPMX is an essential ingredient to your Digital Thread in manufacturing.

An Award You Say?

Receiving the Dieter W. Bergman IPC Fellowship Award earlier this month, brings reflection on the meaning and importance of work contributed to IPC standard committees, not only by myself, but with other members of Aegis, together with hundreds of peers in the industry, experts in their fields, who collectively recognize the need and value of standards in the industry. But what is an IPC standard, how are they created, and what do they mean for us all?

Sick People Walk Among Us

One down-side of being human is the realization that not everyone can be considered a “team player”, even at a time of crisis when our entire species is being challenged. Whether creating and delivering key medical devices, critical industry products, or even a piece of software, we all need to focus equally on the potential influence of “bad actors”, as well as the efficiency of doing it right first time.

Counterfeit Materials: Protect Your Supply Chain

The rapid advancements and utilization of new technologies is simplifying everyone’s life, enabling us to do things quicker, more intelligently, and more efficiently. However, some people see this as being a way to exploit others.

Digital Fire Fighting with a Quality Management System

The act of “putting out a fire” is associated with resolving an urgent problem. Afterward, we worry about the cause, the consequences, and what knowledge we can gain, or so we believe.

8 Signs Your Material Management Process Needs an Upgrade

The heart of the electronics factory is in its machines. However, even the lines and factories with the smartest and most versatile machines rely on intelligent and consistent support received by the central processes to reach maximum capability.

What is an MES System? Part #3

In this last segment of the series, we finish by looking further into the levels of MES functionality that enables final production to work effectively.

What is MES System? Part #2

In this segment of the 3-part series, we will take a more detailed look into the deeper levels of MES, discussing other areas within the factory that MES manages, that enable the final production flow to work smoothly and effectively.

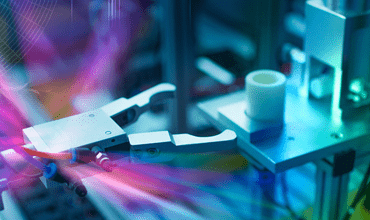

The Importance Of Digital Traceability In Manufacturing

Traceability, in this new age of digital manufacturing, has never been so inexpensive, and with the recently increasing ingress of counterfeit materials, never more important.

Lean Materials Management - WMS and MES

In this blog post, we cover highlights from a recent webinar with Aegis Software and Vecna Robotics: Breaking Down Islands for Lean Manufacturing. Read on to find out how leading manufacturers are creating a truly adaptive and totally visible factory with AGV, MES and WMS together with lean manufacturing concepts.

Software or Ransomware? MES Evaluation to go Digital

Many software systems in use in manufacturing today are holding the business to ransom. Well-meaning, mainly internally developed software utilities, have established a critical dependency on themselves.

APEX 2018 – The Industrial IoT Event Of The Decade – Part 2

Well, if after my last blog about the IPC APEX show, there was excitement and expectation, people who then went to the show, or joined in from all over the world to see the CFX data being collected live, were not disappointed.

SMT-AI Show Rosemont & CFX Update

SMTAI Rosemont was busier this year than the last two years. A major focus in technology as interest in Smart, digital factories and even Industry 4.0. IPC meetings focused on industry leader’s know-how forming consensus-based standards.

SMT-AI Show Rosemont Chicago

SMTAI Rosemont is a “must” on the calendar for manufacturers of any size or sector who want to see how to get with the trend, digitization in manufacturing and using it to take their operations to the next level, rather than be left behind.

How a Manufacturer Used MES Automation for Quality and Compliance

Manufacturers face critical demands to uphold regulatory compliance while driving customer value. Moving from a manual tracking system to an automated MES offers quality control and the flexibility to respond to changes in real time.

Dynamic Manufacturing Dashboard Software – The Tools of the Transparent Factory

Most recently viewing methods have become a critical factor when data is being utilized by an organization. Mobility is the norm in modern business and the team’s ability to stay connected to the data via mobile analytics has become key.

Data Driven Manufacturing: Right Data, Right Place, Right Time

The basic requirement of a successful data driven, or ‘transparent’ factory are the ability to collect data and to store data centrally.

Benefits of Big Data in Manufacturing and Traceability

Taking a big data approach is a change of mindset. In real terms it is all about viewing big data as the means to drive manufacturing excellence through an entire workflow, where traceability becomes a valuable byproduct rather than a cost.

Moving from Reactive to Proactive Traceability in Manufacturing

If traceability is to offer real value, and not cost, then it needs to become proactive, creating traceability data as a byproduct of a data driven manufacturing excellence strategy.

Key Requirements of a Manufacturing Operations Management Solution

When a manufacturing enterprise adopts a Manufacturing Operations Management (MOM) system capable of managing the entire scope of operations, traceability is no longer something an enterprise strives to achieve, it is a byproduct…

Examining the Medical Electronic Supply Chain

Fanatical traceability and regulation in an industry that deals with life and death in a daily basis.

Supply Chain Traceability for Wearables

Since the start of the year and my visit to CES (Consumer Electronics Show) in Las Vegas I, along with most of the industry, have been talking about this new sector and the potential it holds.

Examining the Automotive Electronics Supply Chain

The automotive electronics segment is worth close to $180 Billion annually, plus another $35 Billion for infotainment, and this is a segment with current and projected double-digit growth.

6 Supply Chain Predictions for 2015

A new year and new challenges. What does 2015 have install for those involved in electronics manufacturing up and down the supply chain?

Traceability Comes of Age with Industry 4.0 in Manufacturing

Not so long ago, traceability was predominantly a function required only by certain quality sensitive manufacturers, particularly those within the automotive, medical, military and aerospace sectors.