The Power of Traceability: The Ultimate Shield Against Recall Risks

This blog discusses how manufacturing execution system benefits extend well beyond the realm of improved productivity and reduced waste, offering you a robust means to ensure traceability and, subsequently, compliance.

SMTA CALCE Counterfeit Material Symposium

At the upcoming CALCE UK 2023, Michael Ford of Aegis Software, Damian Glover of Wider.Team and Lubna Dajani of Allternet.com will be discussing how to achieve traceability throughout the supply-network without the need to necessarily change internal processes, domain-based traceability standards, existing solutions and existing data storage methodologies.

DPMX And The Digital Thread

Building your tree of knowledge, your Digital Thread, contextualized based on clear design information with IPC-2581 DPMX, should be one of the most important steps that you can take to ensure success in your Digital Transformation of manufacturing practices. This blog post discusses why design data, in the form of IPC-2581 DPMX is an essential ingredient to your Digital Thread in manufacturing.

How to Solve the 'Rubik's Cube' of Manufacturing Digitalization

A combination puzzle like the Rubik's Cube is a strong analogy for manufacturing today. With so many moving pieces in play, trying to align processes, systems, data, workflows, and more can feel challenging, if not nearly impossible. Let's expand upon this analogy a little more.

Prioritizing Manufacturing Process Optimization

During times of economic volatility, digital transformation is the key to the survival of manufacturing organizations, and enhancing process optimization is critical for thriving through times of change. In this blog post, we explore what Best-in-Class manufacturers are doing to navigate today’s complex manufacturing landscape.

Maneuvering the Manufacturing Maze

This blog post covers the impact of COVID-19 on digital strategies, today’s top business initiatives, how organizations are responding to disruptions, and how the right manufacturing operations platform will enable data-driven decision making, digitization, innovation, and re-imagining.

Take a Look Out of the Window

Using paperless work instructions, no matter how clear they may be, will always benefit from having the opportunity to interact in three dimensions with the assembly that you are making.

The IPC Digital Twin: The Quality Perspective

Any piece of manufacturing software has within it, an element of a digital twin. This has always been the case, as computer applications by definition, work with data that represents physical things or events, using the data to perform tasks which after computation, influence the physical world. The limitation of any digital twin solution in the market therefore, is exactly the same as for a computerized solution. The better the data, the better the capability and the result.

Sick People Walk Among Us

One down-side of being human is the realization that not everyone can be considered a “team player”, even at a time of crisis when our entire species is being challenged. Whether creating and delivering key medical devices, critical industry products, or even a piece of software, we all need to focus equally on the potential influence of “bad actors”, as well as the efficiency of doing it right first time.

Counterfeit Materials: Protect Your Supply Chain

The rapid advancements and utilization of new technologies is simplifying everyone’s life, enabling us to do things quicker, more intelligently, and more efficiently. However, some people see this as being a way to exploit others.

Digital Fire Fighting with a Quality Management System

The act of “putting out a fire” is associated with resolving an urgent problem. Afterward, we worry about the cause, the consequences, and what knowledge we can gain, or so we believe.

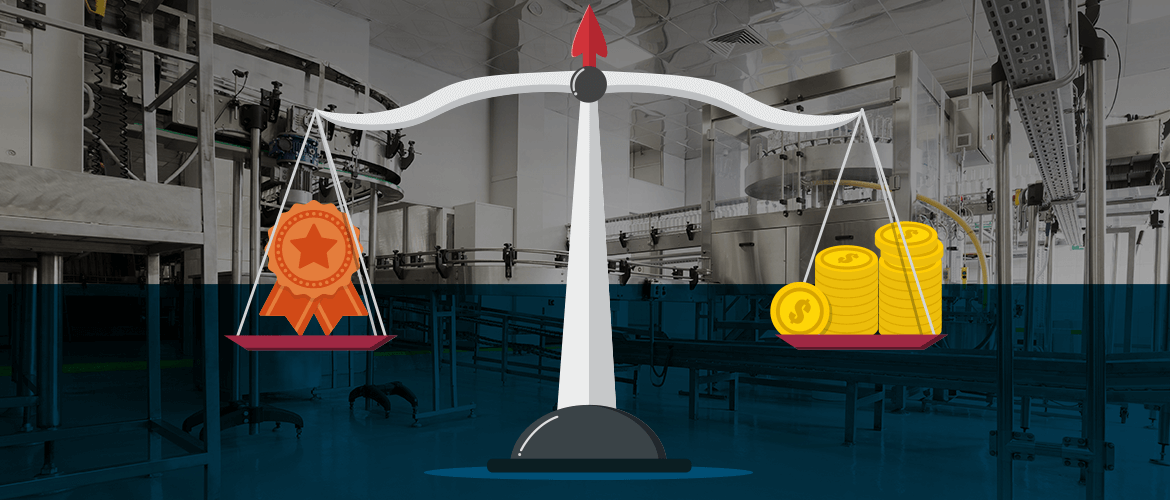

Redefining the Cost-Quality Relationship with Holistic MES + QMS

Today’s discrete manufacturers are under pressure to meet two often-opposing objectives: delight customers with high-quality products, and continually reduce operational costs while doing it.

Accelerating Your Manufacturing Quality System Actionability With MES

Aerospace manufacturers need a quality system. The difference is how readily one reacts to a non-conformance and how frequently they report quality metrics. Without MES, reporting is historical and is often too late to act on its findings.

7 Reasons Why Quality Management Systems Fail

Quality management systems often fail when managers do not use them to their full advantage or lack the knowledge on how to use them properly.

Buyer Beware Is a Bad China Manufacturing Outsourcing Strategy

I wasn’t able to watch 60 Minutes last week to see the story everyone is talking about – toxic, carcinogenic laminate floors imported from China.