Overcoming Challenges With Adaptive Systems and Real-Time Manufacturing Analytics

This blog post will review adaptive manufacturing, discuss the challenges manufacturers face in handling modern-day production, and present solutions for forward-thinking manufacturers that enable real-time factory awareness to drive efficiency throughout the supply chain framework.

Successful Industrial Transformation (IX) Begins with Industrial Operations

According to LNS Research, Industrial Transformation (IX) is defined as a proactive and coordinated approach to leverage digital technologies to create step-change improvements in industrial operations. Today, around 45 percent of companies are currently executing an IX program. But just because an organization is executing an IX program does not mean it is experiencing the benefits of IX. In fact, it is estimated that 15 percent of companies are stuck in the pilot phase.

Your Industry 4.0 Journey

As momentum around the Connected Factory continues to build, manufacturers are focused on reaching Industry 4.0 in their own factory environments. But to reach Industry 4.0 implies that it is a destination—and that, once reached, one’s quest for Industry 4.0 is complete. However, to reap the full benefits of the Connected Factory, it is critical that manufacturers approach Industry 4.0 as a journey.

How Leaders are Leading in Industrial Transformation

It’s no secret that technology is a heavy focus for today’s manufacturers. Unfortunately, many manufacturers often focus on technology as an end, when in reality, technology is a means to achieving better business outcomes.

5 Challenges to Overcome to Increase Manufacturing Productivity

For manufacturers, productivity is paramount. The rate of global manufacturing growth has slowed, according to the International Yearbook of Industrial Statistics 2019 published by the United Nations Industrial Development Organization.

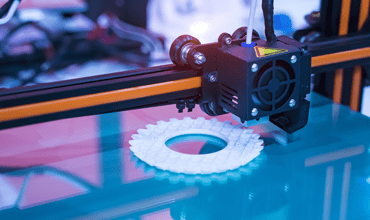

4 Innovative Ways to Improve Manufacturing Productivity

More advanced technology equals higher workforce productivity—this is the simple equation that drives enterprise strategy for many manufacturing leaders.

Augmented Reality - Delivering Value in Smart Factories

With companies like Microsoft promoting their HoloLens for design and manufacturing environments, Augmented Reality (AR) is finding its way into today’s factory, promising value through increased visibility.

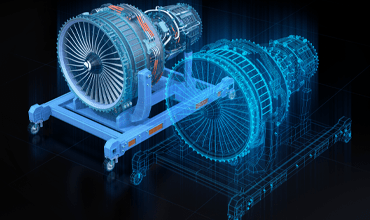

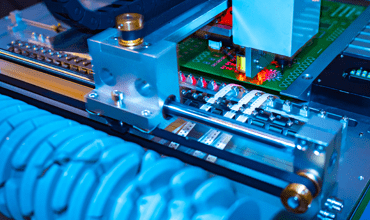

Leveraging Digital Twin Technology to Drive Efficiency

What is a Digital Twin and how are manufacturers leveraging this concept to drive efficiency in an Industry 4.0 environment? SCOOP Founder Phil Stoten interviews Oren Manor, Director at Mentor, and Jason Spera, CEO of Aegis Software.

The Changing World of Productronica 2017

Productronica used to be about evolving machine and materials technology. Not anymore, factories focus more on high-performance flexibility than speed alone. Western manufacturing is more like rallying than a drag-race.

Aegis 2018 User Group Meetings

We recently held an Aegis Software user group meeting, the first to occur in the UK. Face-to-face meetings may seem “old-fashioned” but in this world of increasing digitalization, the values of the face to face communication persist.

How a Manufacturer Used MES Automation for Quality and Compliance

Manufacturers face critical demands to uphold regulatory compliance while driving customer value. Moving from a manual tracking system to an automated MES offers quality control and the flexibility to respond to changes in real time.

The Evolution of Manufacturing Software Packages

Software user-interface is not just about making a pretty picture, but more the user experience and the value received. Depending on the software design, the value from different solutions with similar specifications can differ greatly.

Five Things to Consider Before Selecting a MES Provider

Before you invest in a Manufacturing Execution System (MES) for your facility, you need to consider how easily and efficiently it will be deployed throughout your operation, and what the long-term relationship with your vendor will be like.

Jason Spera talks Industry 4.0 with Kim Sauer at APEX 2016

In an interview with Kim Sauer, at APEX 2016 in Las Vegas, Jason explains how Industry 4.0 goes beyond communication around the SMT line and highlights how materials management is a key component a fully integrated SMART Factory approach.

The Benefits of Engineering: Why We Love Engineers

It doesn’t matter which tech company you admire, engineers largely start them all, be they hardware guys like Steve Wozniak, or software guys like Mark Zuckerberg.

Showtime for Aegis in February and March

As I mentioned in one of my previous blogs, 2015 closed on the heels of a very successful presence at Productronica in Munich, Germany.

Who Drives Innovative Manufacturing Processes?

The manufacturing world has been turned on its head by the outsourcing industry, and in many ways for the better, but what about the impact this trend has had on innovation in the manufacturing process?

Dynamic Manufacturing Dashboard Software – The Tools of the Transparent Factory

Most recently viewing methods have become a critical factor when data is being utilized by an organization. Mobility is the norm in modern business and the team’s ability to stay connected to the data via mobile analytics has become key.

Data Driven Manufacturing: Right Data, Right Place, Right Time

The basic requirement of a successful data driven, or ‘transparent’ factory are the ability to collect data and to store data centrally.

Reasons to go Paperless: Much More than Just Digitizing Documents

People’s perception of what constitutes the paperless shop floor may vary from individual to individual and indeed from company to company.

Benefits of Going Paperless at Work: Paperless Enlightenment

The benefits of going paperless are many, including reductions in costs in terms of print consumables, people’s time and waste due to errors.

Key Requirements of a Manufacturing Operations Management Solution

When a manufacturing enterprise adopts a Manufacturing Operations Management (MOM) system capable of managing the entire scope of operations, traceability is no longer something an enterprise strives to achieve, it is a byproduct…

Blurred and Disrupted: The Impact of Industry Crossover

There was a time, not so long ago, where we knew what each industry did. The automotive industry made cars, the apparel industry made clothes and the electronics industry made electronics. Now everything is a little less clear.

If Not EMS, then What? The Case for Manufacturing Product Fulfillment

It seems we're in a phase where the term EMS does really cover what the companies we think of as electronics manufacturing service providers actually do.

Five Reasons to Move to Contract Manufacturing Outsourcing (And None of Them Are Price!)

There are many compelling reasons to consider outsourcing of the product supply chain, be it from design to delivery or merely PCB assembly. And while this can, and often does, result in cost reduction it really shouldn’t be the motivation.

Examining the Automotive Electronics Supply Chain

The automotive electronics segment is worth close to $180 Billion annually, plus another $35 Billion for infotainment, and this is a segment with current and projected double-digit growth.

Buyer Beware Is a Bad China Manufacturing Outsourcing Strategy

I wasn’t able to watch 60 Minutes last week to see the story everyone is talking about – toxic, carcinogenic laminate floors imported from China.

Manufacturing Supply Chain Strategy as a Competitive Advantage

I think supply chain is sexy, but more importantly I think supply chain can be a real competitive advantage in all parts of the electronics manufacturing industry.

Teamwork in China

You’ve got great people in China, but do you know how well they work as a team?

Manufacturing Job Trends for 2015

Remember a few years ago when geek became chic? No, me neither, but apparently it did, and programmers became cool and among the best paid people in Silicon Valley.

Elements of Strategic Sourcing Strategy – When do you start?

Most think that strategic sourcing should start when it’s time to introduce product into production, making decisions about where to source components and what the assembly strategy should be, right?

4 Benefits of Manufacturing Software for Continuous Improvement

Progress toward Operational Excellence requires the strategic alignment and then optimization of key resources: people, processes, and technology. Each of these three resource categories contributes its own individual, unique value.

Why Operational Excellence in Manufacturing Must Expand in 2015

The business world in general has become increasingly global and distributed, which has both benefitted and challenged manufacturers in multiple ways.

6 Supply Chain Predictions for 2015

A new year and new challenges. What does 2015 have install for those involved in electronics manufacturing up and down the supply chain?

4 Ways Manufacturing Leaders Can Shape Operational Excellence Strategy

Experienced professionals know that buy-in from senior leadership is often the greatest success factor for an initiative.

Traceability Comes of Age with Industry 4.0 in Manufacturing

Not so long ago, traceability was predominantly a function required only by certain quality sensitive manufacturers, particularly those within the automotive, medical, military and aerospace sectors.

The Anatomy of an Operational Excellence Program

Most companies—especially large ones—seem to have some form of continuous improvement program. With today’s dynamic and turbulent global economy, programs like ISO 9001 or Lean Manufacturing are critical for sustaining competitiveness.

Operational Excellence Starts Here. Today.

For 17 years, Aegis’ mission has been to reshape the very concept of MES toward a more comprehensive and yet cost-effective solution for manufacturers.