The State of Digital Manufacturing: A Pulse Check on Industry Transformation

There are a lot of buzzwords and vendor solutions when it comes to the manufacturing tech space, which is making it very hard for companies to navigate and know which ones will provide the biggest impact. This blog delves into the state of digital manufacturing and what manufacturers can do to position themselves better to capitalize on these technological advancements.

From Silos to Success: 6 Essential Steps for Embracing a Holistic Manufacturing Approach

In today's dynamic manufacturing landscape, staying competitive demands a comprehensive focus on process improvement. A holistic approach to digitalization is essential to navigate the intricate web of constraints and possibilities, encompassing the entire manufacturing journey from raw material procurement to the seamless delivery of the final product.

Closing the Manufacturing Skills Gap

This blog explores the progression of technology in manufacturing, the effect of poor knowledge transfer on the skills gap, and how the right systems and technology can enable the connected worker—driving tangible progress in narrowing the gap for the entire industry.

The Power of Traceability: The Ultimate Shield Against Recall Risks

This blog discusses how manufacturing execution system benefits extend well beyond the realm of improved productivity and reduced waste, offering you a robust means to ensure traceability and, subsequently, compliance.

Winning the Race to ROI: Optimizing Time-to-Value for Digital Transformation

This blog post addresses common misconceptions about digital transformation, the challenges manufacturers may face, and a structured implementation framework to drive successful results and shorten the time to achieve a positive ROI.

Why Data Contextualization is Critical During the Digital Transformation Era

This blog post will discuss important considerations for an effective data strategy, reveal why contextualization is critical, and showcase what anintelligent, agile, data-driven, and on-demand enterprise looks like.

Overcoming Challenges With Adaptive Systems and Real-Time Manufacturing Analytics

This blog post will review adaptive manufacturing, discuss the challenges manufacturers face in handling modern-day production, and present solutions for forward-thinking manufacturers that enable real-time factory awareness to drive efficiency throughout the supply chain framework.

eSmartFactory Conference

The eSmartFactory Conference in Europe provides innovative, practical, and adoptable technologies for successful Smart manufacturing. Several presentations including one from Michael Ford will address such things as whether and how AI will change our manufacturing lives.

Revving up for a Smart Future: Exploring the Digitalization Era in Manufacturing

Manufacturers are continually facing challenges and changes as they embrace Industry 4.0 practices to stay competitive in today’s environment. In this blog post, we discuss the pressures on today’s manufacturers and how key digitalization drivers are shaping digital transformation.

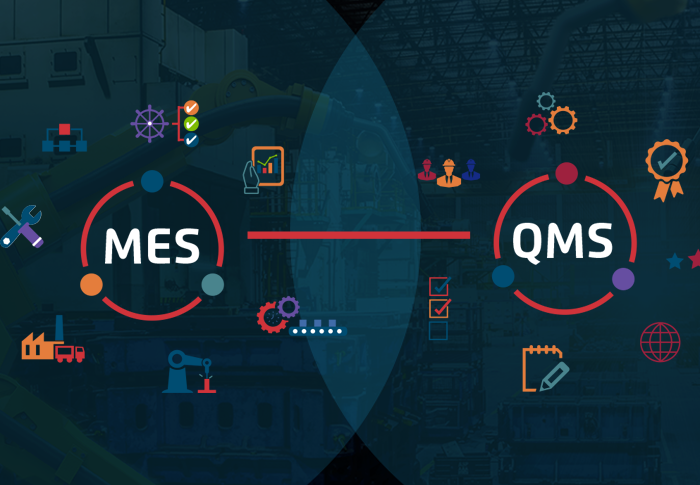

How Holistic MES + QMS Work Together to Elevate Quality

This blog discusses why data is a crucial driver of quality, how to achieve holistic quality management, and why a holistic MES and QMS platform is the key to achieving a more efficient supply chain.

Leading with Quality in the Digital Transformation Era

In this blog post, we review the state of quality in manufacturing, discuss how digital technology is transforming quality management, and surface what best-in-class companies are doing to ensure quality in a tangible way.

DPMX And The Digital Thread

Building your tree of knowledge, your Digital Thread, contextualized based on clear design information with IPC-2581 DPMX, should be one of the most important steps that you can take to ensure success in your Digital Transformation of manufacturing practices. This blog post discusses why design data, in the form of IPC-2581 DPMX is an essential ingredient to your Digital Thread in manufacturing.

How an MES Plays a Critical Role in the Complex Manufacturing Process

This blog post discusses the tangible benefits an MES can bring to manufacturing companies when complemented with a robust QMS and why implementing the right system is so important.

Achieving Digital Dominance in Manufacturing through Data, Talent & Technology

While it is true that there are a multitude of unprecedented problems facing manufacturers, there are also many exciting opportunities for growth and innovation. The most forward-thinking manufacturers are laser-focused on transforming their operations through digital technology. In this blog post, we'll look closely at top challenges for today's manufacturers, key ways to mitigate issues, and how the right MES can help you attain digital dominance.

Lean Materials Management: How to Maximize Productivity While Minimizing Inventory

A truly efficient manufacturing process requires raw materials to arrive at the right location at the right time, enabling manufacturers to minimize the amount of inventory on hand, saving time and money. But without the proper MES in place, this kind of lean materials management may remain an elusive goal.

How to Solve the 'Rubik's Cube' of Manufacturing Digitalization

A combination puzzle like the Rubik's Cube is a strong analogy for manufacturing today. With so many moving pieces in play, trying to align processes, systems, data, workflows, and more can feel challenging, if not nearly impossible. Let's expand upon this analogy a little more.

Prioritizing Manufacturing Process Optimization

During times of economic volatility, digital transformation is the key to the survival of manufacturing organizations, and enhancing process optimization is critical for thriving through times of change. In this blog post, we explore what Best-in-Class manufacturers are doing to navigate today’s complex manufacturing landscape.

Maneuvering the Manufacturing Maze

This blog post covers the impact of COVID-19 on digital strategies, today’s top business initiatives, how organizations are responding to disruptions, and how the right manufacturing operations platform will enable data-driven decision making, digitization, innovation, and re-imagining.

Manufacturing 4.0 Made Possible

This blog delves into the workforce shortages and post-COVID world challenges and explores how system consolidation, data contextualization, and artificial intelligence (AI) can help transform factories into Industry 4.0-enabled powerhouses.

Enhancing Resiliency in Manufacturing through Connected Platforms, Increased Visibility, and Process Optimization

In this blog post, we focus on three ways that Best-in-Class manufacturers have become more resilient in their operations—and three critical steps your organization can take to become more resilient too.

Amplifying Value: The Significant Benefits of Connecting ERP and MES

As pressures on today's manufacturers continue to intensify, Enterprise Resource Planning (ERP) solutions alone are not robust enough to manage all of the modern-day manufacturer's daily tasks and strategic demands. In this blog, we take a closer look at the role of the ERP and MES, quantify some of the benefits of the two systems working together, then examine six specific areas that can amplify value for today's manufacturers.

Is Your Organization a Leader or Laggard in Manufacturing Performance?

To overcome the vast challenges and meet ambitious goals for the future, manufacturers must be operating at the highest level of performance. Unfortunately, however, not every company is configured to achieve its full performance potential. Is yours?

Aegis Software Steps Up To Help New And Existing e-Mobility Manufacturers

As automotive today gives way to e-Mobility, revolutionary changes are happening, that bring a whole new generation of opportunity at every level of the manufacturing process.

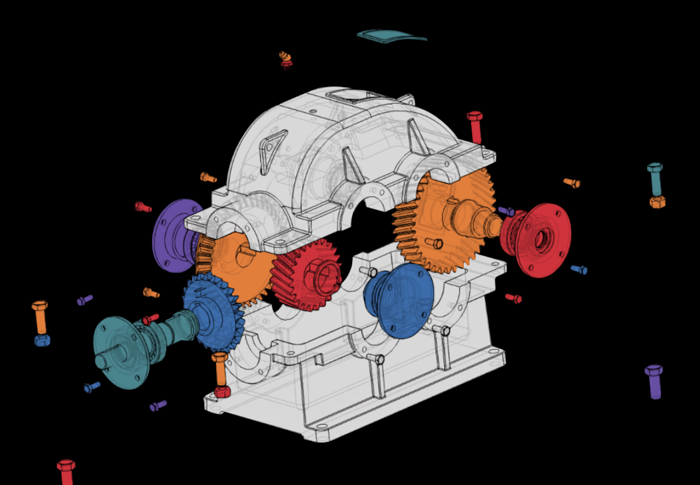

Take a Look Out of the Window

Using paperless work instructions, no matter how clear they may be, will always benefit from having the opportunity to interact in three dimensions with the assembly that you are making.

Discrete Manufacturers Discover Value in New MES/MOM Solutions

In this recent Automation.com interview article, Jason Spera, shares his vantage of the changes for factory floor automation in 2021.

Next-Gen Technologies to Navigate Key Shifts in Industrial Manufacturing

The multitude of challenges that manufacturers face today is accelerating the need to adapt process innovation, embrace technology, and digitalize operations. Transformation is essential for manufacturers to become more resilient, agile, productive, and profitable throughout Industry 4.0.

The Road to Industry 4.0 Doesn’t Have to be Rocky

Industry 4.0 is revolutionizing manufacturing processes today by bridging the gap between high-level Information Technology and floor-level Operational Technology—all while leveraging intelligent data insights to power factory-wide analytics.

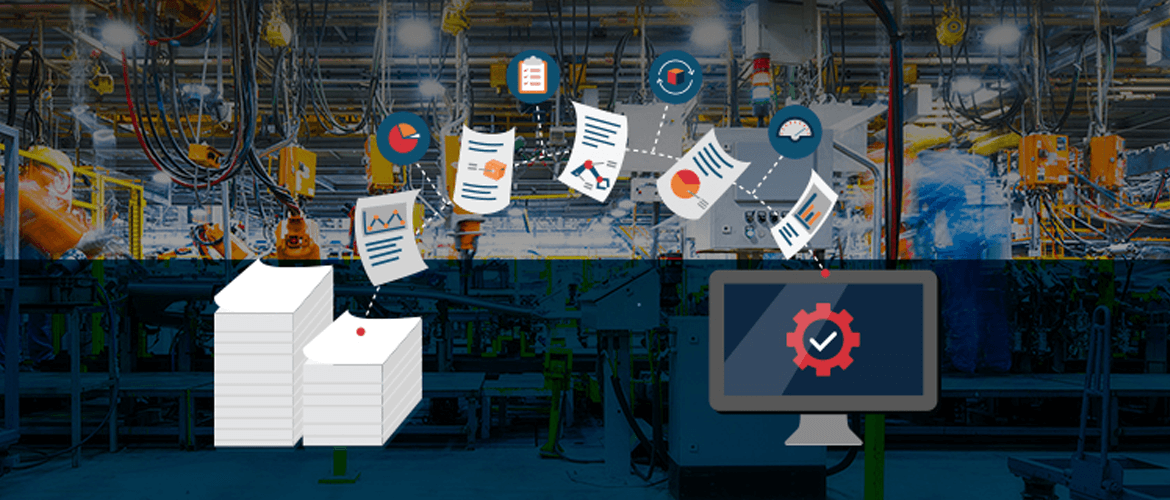

The Path to a Paperless Shop Floor

Paper-based processes can no longer keep up with real-time demands or scale with changing business requirements. When manufacturers use manual, paper-based systems, human error, and poor data integrity permeate all business areas. For this reason, and many others, Best-In-Class manufacturers, are increasingly turning to digital solutions.

3 Key Steps in Building Your MES Business Case

Today’s fast-paced manufacturers are under tremendous pressure to increase throughput, reduce costs, ensure quality, and enable product personalization. It, therefore, makes sense that manufacturing organizations across sectors are increasingly adopting the MES (Manufacturing Execution System) as a powerful solution that provides real-time visibility and control over operations in support of greater agility and optimization.

Sick People Walk Among Us

One down-side of being human is the realization that not everyone can be considered a “team player”, even at a time of crisis when our entire species is being challenged. Whether creating and delivering key medical devices, critical industry products, or even a piece of software, we all need to focus equally on the potential influence of “bad actors”, as well as the efficiency of doing it right first time.

Your Industry 4.0 Journey

As momentum around the Connected Factory continues to build, manufacturers are focused on reaching Industry 4.0 in their own factory environments. But to reach Industry 4.0 implies that it is a destination—and that, once reached, one’s quest for Industry 4.0 is complete. However, to reap the full benefits of the Connected Factory, it is critical that manufacturers approach Industry 4.0 as a journey.

Counterfeit Materials: Protect Your Supply Chain

The rapid advancements and utilization of new technologies is simplifying everyone’s life, enabling us to do things quicker, more intelligently, and more efficiently. However, some people see this as being a way to exploit others.

How Leaders are Leading in Industrial Transformation

It’s no secret that technology is a heavy focus for today’s manufacturers. Unfortunately, many manufacturers often focus on technology as an end, when in reality, technology is a means to achieving better business outcomes.

Key Points to Consider When it Comes to Manufacturing Cloud Data

People have begun describing their cloud systems as "the fog." I get the feeling the joke is based on actual events. Are we" venting" gases into the atmosphere with our data during this digital era just like we did during the industrial age?

The Future of the Paperless Factory

Eliminating paper in manufacturing, also known as the Smart Factory or Industry 4.0, is just the first step of the digital revolution.

5 Challenges to Overcome to Increase Manufacturing Productivity

For manufacturers, productivity is paramount. The rate of global manufacturing growth has slowed, according to the International Yearbook of Industrial Statistics 2019 published by the United Nations Industrial Development Organization.

4 Innovative Ways to Improve Manufacturing Productivity

More advanced technology equals higher workforce productivity—this is the simple equation that drives enterprise strategy for many manufacturing leaders.

What is an MES System? Part #3

In this last segment of the series, we finish by looking further into the levels of MES functionality that enables final production to work effectively.

Electronics Manufacturing Services [EMS] - Need For Speed Is Not Only In Production

Could anyone have imagined the degree to which our world has become automated? From smartphones to fully automated data centers, we’ve experienced a technological revolution that has digitized everything.

What is MES System? Part #2

In this segment of the 3-part series, we will take a more detailed look into the deeper levels of MES, discussing other areas within the factory that MES manages, that enable the final production flow to work smoothly and effectively.

Redefining the Cost-Quality Relationship with Holistic MES + QMS

Today’s discrete manufacturers are under pressure to meet two often-opposing objectives: delight customers with high-quality products, and continually reduce operational costs while doing it.

What is an MES System? Part #1

Eliminating paper in manufacturing, also known as the Smart Factory or Industry 4.0, is just the first step of the digital revolution.

Lean Materials Management - WMS and MES

In this blog post, we cover highlights from a recent webinar with Aegis Software and Vecna Robotics: Breaking Down Islands for Lean Manufacturing. Read on to find out how leading manufacturers are creating a truly adaptive and totally visible factory with AGV, MES and WMS together with lean manufacturing concepts.

Software or Ransomware? MES Evaluation to go Digital

Many software systems in use in manufacturing today are holding the business to ransom. Well-meaning, mainly internally developed software utilities, have established a critical dependency on themselves.

SMT Hybrid Packaging Show Nuremberg – What’s Not To Miss

SMT Hybrid Packaging show, taking place in Nuremberg from the 5th to the 7th of June, takes the strain as the focus of attention for technology and innovation in the electronics assembly manufacturing market.

MES & ERP Together – Top Integration Benefits For Manufacturers

Today’s shop floor is a highly-complex, continually-shifting environment. A recent study by Aberdeen Group polled today’s best-in-class manufacturers and found the top reported pressures of modern manufacturing.

Accelerating Your Manufacturing Quality System Actionability With MES

Aerospace manufacturers need a quality system. The difference is how readily one reacts to a non-conformance and how frequently they report quality metrics. Without MES, reporting is historical and is often too late to act on its findings.

Driving a Digital Transformation with MES System Integrators

Atrenne Integrated Solutions, customers include Aerospace and Defense companies, requiring the utmost quality control and production efficiency. Aegis’ FactoryLogix MES offers real-time visibility, streamlined processes and ensures quality.

Building a House of Cards: The Future of Manufacturing Technology

Challenges like Industry 4.0 are turning the manufacturing world upside down, in a good way, we see solutions being quite brutally put together, through acquisition or partnership, which are expected to be seen as the solutions of tomorrow.

The Evolution of Manufacturing Software Packages

Software user-interface is not just about making a pretty picture, but more the user experience and the value received. Depending on the software design, the value from different solutions with similar specifications can differ greatly.

The Ever Greener Grass of SMT Manufacturing

What we think we know is a less dynamic concept than actual reality. Many things progress so quickly, that we simply cannot keep up any longer. How do we know whether the grass is really greener on the other side?

Five Things to Consider Before Selecting a MES Provider

Before you invest in a Manufacturing Execution System (MES) for your facility, you need to consider how easily and efficiently it will be deployed throughout your operation, and what the long-term relationship with your vendor will be like.

MES Embracing IIoT Analytics Remains Hottest IIoT Space

The #MondayMusings blog series provides executive level insights and analysis for the Industrial Internet of Things (IIoT) and Digital Transformation from the previous week’s briefings, events, and publications @LNSResearch.

Robots and Re-Shoring – Can Robots Save Jobs?

It’s an odd premise but more than one person at APEX in Las Vegas told me that robots could be part of the drive to save manufacturing jobs in places like the USA where labor rates are higher.

The Art of Manufacturing Vendor Selection – top ten hints

Alibaba and DigiKey is not a supply chain strategy! So what are the ten most important things to consider when developing an outsourced manufacturing solution and the supply chain that surrounds it?

Showtime for Aegis in February and March

As I mentioned in one of my previous blogs, 2015 closed on the heels of a very successful presence at Productronica in Munich, Germany.

Dynamic Manufacturing Dashboard Software – The Tools of the Transparent Factory

Most recently viewing methods have become a critical factor when data is being utilized by an organization. Mobility is the norm in modern business and the team’s ability to stay connected to the data via mobile analytics has become key.

Why a Paperless Factory Benefits Everyone

We all know that for any change to be successful everyone must benefit. Nowhere is this truer than in the change to a paperless factory floor environment.

Key Requirements of a Manufacturing Operations Management Solution

When a manufacturing enterprise adopts a Manufacturing Operations Management (MOM) system capable of managing the entire scope of operations, traceability is no longer something an enterprise strives to achieve, it is a byproduct…

Blurred and Disrupted: The Impact of Industry Crossover

There was a time, not so long ago, where we knew what each industry did. The automotive industry made cars, the apparel industry made clothes and the electronics industry made electronics. Now everything is a little less clear.

4 Benefits of Manufacturing Software for Continuous Improvement

Progress toward Operational Excellence requires the strategic alignment and then optimization of key resources: people, processes, and technology. Each of these three resource categories contributes its own individual, unique value.

Why Operational Excellence in Manufacturing Must Expand in 2015

The business world in general has become increasingly global and distributed, which has both benefitted and challenged manufacturers in multiple ways.

4 Ways Manufacturing Leaders Can Shape Operational Excellence Strategy

Experienced professionals know that buy-in from senior leadership is often the greatest success factor for an initiative.

The Anatomy of an Operational Excellence Program

Most companies—especially large ones—seem to have some form of continuous improvement program. With today’s dynamic and turbulent global economy, programs like ISO 9001 or Lean Manufacturing are critical for sustaining competitiveness.

Operational Excellence Starts Here. Today.

For 17 years, Aegis’ mission has been to reshape the very concept of MES toward a more comprehensive and yet cost-effective solution for manufacturers.