The IPC Digital Twin: The Quality Perspective

Any piece of manufacturing software has within it, an element of a digital twin. This has always been the case, as computer applications by definition, work with data that represents physical things or events, using the data to perform tasks which after computation, influence the physical world. The limitation of any digital twin solution in the market therefore, is exactly the same as for a computerized solution. The better the data, the better the capability and the result.

The Value of Data is Much More Than Just Analysis

Today too many companies are focused on the acquisition of data in the hopes that the data will create value. Industry 4.0 examines more than the simple internal machine stoppages. Industry 4.0 is focused on the analysis of time intervals in which there is zero data because the equipment or process is not actually working.

Successful Industrial Transformation (IX) Begins with Industrial Operations

According to LNS Research, Industrial Transformation (IX) is defined as a proactive and coordinated approach to leverage digital technologies to create step-change improvements in industrial operations. Today, around 45 percent of companies are currently executing an IX program. But just because an organization is executing an IX program does not mean it is experiencing the benefits of IX. In fact, it is estimated that 15 percent of companies are stuck in the pilot phase.

How Leaders are Leading in Industrial Transformation

It’s no secret that technology is a heavy focus for today’s manufacturers. Unfortunately, many manufacturers often focus on technology as an end, when in reality, technology is a means to achieving better business outcomes.

Deploying an Industry 4.0 Solution In-House, OutSourced or Jointly

The promise of the benefits that can be reaped from big data and predictive analytics through access to machine and operator data is compelling enough for most manufacturers to seriously direct their IT and OT departments to look into ways to enable such machine and operator data acquisition.

Key Points to Consider When it Comes to Manufacturing Cloud Data

People have begun describing their cloud systems as "the fog." I get the feeling the joke is based on actual events. Are we" venting" gases into the atmosphere with our data during this digital era just like we did during the industrial age?

How IPC Connected Factory Exchange is Leveling the Playing Field

The catalyst for the now long-awaited Industry 4.0 revolution is the introduction of the IPC CFX (Connected Factory Exchange) standard for IIoT.

Industry 4.0 Concepts: Cyber Physical System, IOT, Digital Twin

The Cyber Physical System (CPS), Internet of Things (IoT) and Digital Twin are all central concepts in Industry 4.0, often used interchangeably in discussions about Industry 4.0 and smart manufacturing.

4 Innovative Ways to Improve Manufacturing Productivity

More advanced technology equals higher workforce productivity—this is the simple equation that drives enterprise strategy for many manufacturing leaders.

The CFX & FactoryLogix Advantage

For anyone currently considering investment in a modern digital manufacturing solution, inclusive of any form of discrete assembly manufacturing, it is imperative that expectations and requirements are redefined in the light of this new IIoT.

What is an MES System? Part #3

In this last segment of the series, we finish by looking further into the levels of MES functionality that enables final production to work effectively.

What is MES System? Part #2

In this segment of the 3-part series, we will take a more detailed look into the deeper levels of MES, discussing other areas within the factory that MES manages, that enable the final production flow to work smoothly and effectively.

The Importance Of Digital Traceability In Manufacturing

Traceability, in this new age of digital manufacturing, has never been so inexpensive, and with the recently increasing ingress of counterfeit materials, never more important.

Software or Ransomware? MES Evaluation to go Digital

Many software systems in use in manufacturing today are holding the business to ransom. Well-meaning, mainly internally developed software utilities, have established a critical dependency on themselves.

Shaping Your Industry 4.0 IIoT Journey

In this blog post we’ll cover four potential starting points to jump start your efforts. Keep in mind that each of these key elements of digital innovation—IIoT connectivity, smart applications, and advanced analytics—will eventually play a critical role in your factory.

SMT Hybrid Packaging Show Nuremberg – What’s Not To Miss

SMT Hybrid Packaging show, taking place in Nuremberg from the 5th to the 7th of June, takes the strain as the focus of attention for technology and innovation in the electronics assembly manufacturing market.

MES & ERP Together – Top Integration Benefits For Manufacturers

Today’s shop floor is a highly-complex, continually-shifting environment. A recent study by Aberdeen Group polled today’s best-in-class manufacturers and found the top reported pressures of modern manufacturing.

APEX 2018 – The Industrial IoT Event Of The Decade – Part 2

Well, if after my last blog about the IPC APEX show, there was excitement and expectation, people who then went to the show, or joined in from all over the world to see the CFX data being collected live, were not disappointed.

APEX 2018 – The Industrial IoT Event Of The Decade

If you are one of the few remaining people who has not heard about the event of the decade coming up at the APEX tradeshow at the end of this month, you really need to read on.

Augmented Reality - Delivering Value in Smart Factories

With companies like Microsoft promoting their HoloLens for design and manufacturing environments, Augmented Reality (AR) is finding its way into today’s factory, promising value through increased visibility.

2018 – The Year Of IoT Digitalization

This time last year, many people, including myself, were confident that 2017 would be the year of shop-floor IoT communication. While progress has been strong, 2018 looks more realistic for practical application of IoT in manufacturing.

Leveraging Digital Twin Technology to Drive Efficiency

What is a Digital Twin and how are manufacturers leveraging this concept to drive efficiency in an Industry 4.0 environment? SCOOP Founder Phil Stoten interviews Oren Manor, Director at Mentor, and Jason Spera, CEO of Aegis Software.

The Changing World of Productronica 2017

Productronica used to be about evolving machine and materials technology. Not anymore, factories focus more on high-performance flexibility than speed alone. Western manufacturing is more like rallying than a drag-race.

Aegis 2018 User Group Meetings

We recently held an Aegis Software user group meeting, the first to occur in the UK. Face-to-face meetings may seem “old-fashioned” but in this world of increasing digitalization, the values of the face to face communication persist.

Driving a Digital Transformation with MES System Integrators

Atrenne Integrated Solutions, customers include Aerospace and Defense companies, requiring the utmost quality control and production efficiency. Aegis’ FactoryLogix MES offers real-time visibility, streamlined processes and ensures quality.

Top Manufacturing Industry Trends for 2017

As we look back on 2016, it’s only natural to reflect on what’s ahead for global manufacturing in the coming year. Let’s take a look at the top manufacturing trends for 2017.

Five Things to Consider Before Selecting a MES Provider

Before you invest in a Manufacturing Execution System (MES) for your facility, you need to consider how easily and efficiently it will be deployed throughout your operation, and what the long-term relationship with your vendor will be like.

MES Embracing IIoT Analytics Remains Hottest IIoT Space

The #MondayMusings blog series provides executive level insights and analysis for the Industrial Internet of Things (IIoT) and Digital Transformation from the previous week’s briefings, events, and publications @LNSResearch.

Electronic Manufacturing Embraces IoM at APEX 2016

Last week in Las Vegas the electronics industry gathered to explore the latest developments, while there were the usual growths as products are getting faster, more efficient and cheaper, there was little revolution except in IoM.

Jason Spera talks Industry 4.0 with Kim Sauer at APEX 2016

In an interview with Kim Sauer, at APEX 2016 in Las Vegas, Jason explains how Industry 4.0 goes beyond communication around the SMT line and highlights how materials management is a key component a fully integrated SMART Factory approach.

Will 2016 be the year that IoT really impacts upon the electronic manufacturing supply chain?

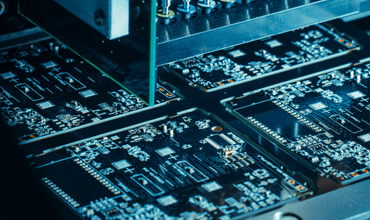

The first industrial revolution was built on machines lubricated by oil, the current revolution is built on computers lubricated by data.

A Golden Age of Innovation in Manufacturing Supply Chain Outsourcing

As I see it a number of factors are throwing up another golden age of electronics innovation, led by new markets and supported by enabling technologies, excellent outsourced product fulfillment and good access to venture capital.

IoT Solutions for Manufacturing and the Supply Chain

Trends around IoM (Internet of Manufacturing) and Industry 4.0 are all largely focused on operations but where does the potential lie for big data within the supply chain?

IoT, community and content at the centre of CES

I’m back in San Jose after CES and thought I’d put down a few thoughts on this year’s exhibition floor, keynotes and presentations.

Data Driven Manufacturing: Right Data, Right Place, Right Time

The basic requirement of a successful data driven, or ‘transparent’ factory are the ability to collect data and to store data centrally.

Manufacturing Job Trends for 2015

Remember a few years ago when geek became chic? No, me neither, but apparently it did, and programmers became cool and among the best paid people in Silicon Valley.

What are the Top IoM Benefits?

What is the Internet of Manufacturing (IoM) and why should we care about it?

Is 2015 the Wearables Year?

Wearables were a big deal at CES (Consumer Electronics Show) at the very opening of 2015, mentioned in numerous keynotes and visible on many booths.

Creating a Smarter Factory Through Factory Process Improvements

Customisation has thus far always been the prerogative of a select few involving a time-intensive process with a complex, fragmented and costly supply chain.

IoT + EMS = Internet of Things in Manufacturing (IoM)

The Internet of Things (IoT) is central to the premise of Industry 4.0, a world where a product self identifies at the start of its life.