Why Data Contextualization is Critical During the Digital Transformation Era

This blog post will discuss important considerations for an effective data strategy, reveal why contextualization is critical, and showcase what anintelligent, agile, data-driven, and on-demand enterprise looks like.

Overcoming Challenges With Adaptive Systems and Real-Time Manufacturing Analytics

This blog post will review adaptive manufacturing, discuss the challenges manufacturers face in handling modern-day production, and present solutions for forward-thinking manufacturers that enable real-time factory awareness to drive efficiency throughout the supply chain framework.

Revving up for a Smart Future: Exploring the Digitalization Era in Manufacturing

Manufacturers are continually facing challenges and changes as they embrace Industry 4.0 practices to stay competitive in today’s environment. In this blog post, we discuss the pressures on today’s manufacturers and how key digitalization drivers are shaping digital transformation.

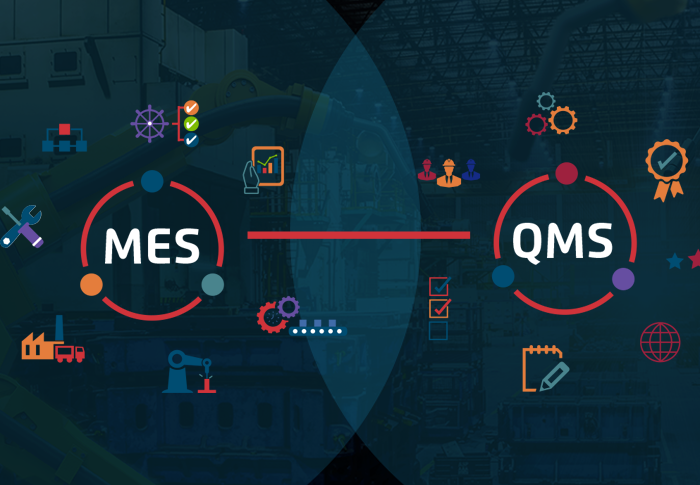

How Holistic MES + QMS Work Together to Elevate Quality

This blog discusses why data is a crucial driver of quality, how to achieve holistic quality management, and why a holistic MES and QMS platform is the key to achieving a more efficient supply chain.

Leading with Quality in the Digital Transformation Era

In this blog post, we review the state of quality in manufacturing, discuss how digital technology is transforming quality management, and surface what best-in-class companies are doing to ensure quality in a tangible way.

DPMX And The Digital Thread

Building your tree of knowledge, your Digital Thread, contextualized based on clear design information with IPC-2581 DPMX, should be one of the most important steps that you can take to ensure success in your Digital Transformation of manufacturing practices. This blog post discusses why design data, in the form of IPC-2581 DPMX is an essential ingredient to your Digital Thread in manufacturing.

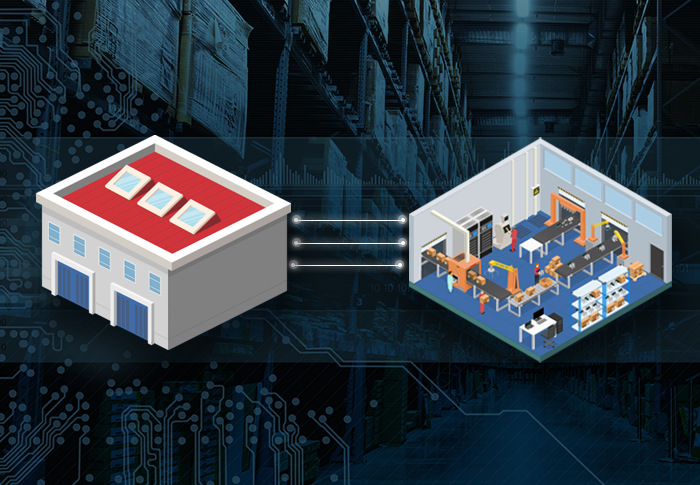

How an MES Plays a Critical Role in the Complex Manufacturing Process

This blog post discusses the tangible benefits an MES can bring to manufacturing companies when complemented with a robust QMS and why implementing the right system is so important.

Achieving Digital Dominance in Manufacturing through Data, Talent & Technology

While it is true that there are a multitude of unprecedented problems facing manufacturers, there are also many exciting opportunities for growth and innovation. The most forward-thinking manufacturers are laser-focused on transforming their operations through digital technology. In this blog post, we'll look closely at top challenges for today's manufacturers, key ways to mitigate issues, and how the right MES can help you attain digital dominance.

Lean Materials Management: How to Maximize Productivity While Minimizing Inventory

A truly efficient manufacturing process requires raw materials to arrive at the right location at the right time, enabling manufacturers to minimize the amount of inventory on hand, saving time and money. But without the proper MES in place, this kind of lean materials management may remain an elusive goal.

How to Solve the 'Rubik's Cube' of Manufacturing Digitalization

A combination puzzle like the Rubik's Cube is a strong analogy for manufacturing today. With so many moving pieces in play, trying to align processes, systems, data, workflows, and more can feel challenging, if not nearly impossible. Let's expand upon this analogy a little more.

Prioritizing Manufacturing Process Optimization

During times of economic volatility, digital transformation is the key to the survival of manufacturing organizations, and enhancing process optimization is critical for thriving through times of change. In this blog post, we explore what Best-in-Class manufacturers are doing to navigate today’s complex manufacturing landscape.

Maneuvering the Manufacturing Maze

This blog post covers the impact of COVID-19 on digital strategies, today’s top business initiatives, how organizations are responding to disruptions, and how the right manufacturing operations platform will enable data-driven decision making, digitization, innovation, and re-imagining.

Manufacturing 4.0 Made Possible

This blog delves into the workforce shortages and post-COVID world challenges and explores how system consolidation, data contextualization, and artificial intelligence (AI) can help transform factories into Industry 4.0-enabled powerhouses.

Enhancing Resiliency in Manufacturing through Connected Platforms, Increased Visibility, and Process Optimization

In this blog post, we focus on three ways that Best-in-Class manufacturers have become more resilient in their operations—and three critical steps your organization can take to become more resilient too.

Is Your Organization a Leader or Laggard in Manufacturing Performance?

To overcome the vast challenges and meet ambitious goals for the future, manufacturers must be operating at the highest level of performance. Unfortunately, however, not every company is configured to achieve its full performance potential. Is yours?

Aegis Software Steps Up To Help New And Existing e-Mobility Manufacturers

As automotive today gives way to e-Mobility, revolutionary changes are happening, that bring a whole new generation of opportunity at every level of the manufacturing process.

Discrete Manufacturers Discover Value in New MES/MOM Solutions

In this recent Automation.com interview article, Jason Spera, shares his vantage of the changes for factory floor automation in 2021.

Next-Gen Technologies to Navigate Key Shifts in Industrial Manufacturing

The multitude of challenges that manufacturers face today is accelerating the need to adapt process innovation, embrace technology, and digitalize operations. Transformation is essential for manufacturers to become more resilient, agile, productive, and profitable throughout Industry 4.0.

An Award You Say?

Receiving the Dieter W. Bergman IPC Fellowship Award earlier this month, brings reflection on the meaning and importance of work contributed to IPC standard committees, not only by myself, but with other members of Aegis, together with hundreds of peers in the industry, experts in their fields, who collectively recognize the need and value of standards in the industry. But what is an IPC standard, how are they created, and what do they mean for us all?

The Road to Industry 4.0 Doesn’t Have to be Rocky

Industry 4.0 is revolutionizing manufacturing processes today by bridging the gap between high-level Information Technology and floor-level Operational Technology—all while leveraging intelligent data insights to power factory-wide analytics.

It's Not What You've Got, It's What You Use That Matters

Acquiring data from the entire factory is just the first step towards improving the manufacturing process using digital solutions. What you do with the data is much more important than merely having it, creating dashboards, performing machine learning, and analyzing it. The real IIoT-based MES digital twin for manufacturing has arrived.