A combination puzzle like the Rubik's Cube is a strong analogy for manufacturing today. With so many moving pieces in play, trying to align processes, systems, data, workflows, and more can feel challenging, if not nearly impossible. Let's expand upon this analogy a little more.

Digitalization in the manufacturing industry is essential but building and implementing your manufacturing digitalization strategy (or Rubik's Cube) can feel overwhelming. Like a Rubik's Cube, there's more than one way to solve the puzzle; there are no shortcuts; it's easy only to get one face right, and as complexity increases, so does the chaos. Ultimately, without all the pieces in the right places, achieving one's end goals is very difficult.

However, with the right system, all of the pieces can come together to solve the elusive puzzle. This blog post will explore examples on how to apply lessons learned from the Rubik's Cube analogy to your digitalization efforts to survive and succeed as we navigate continuously uncertain times in the manufacturing industry.

The 'Rubik's Cube' of Manufacturing Digitalization Today

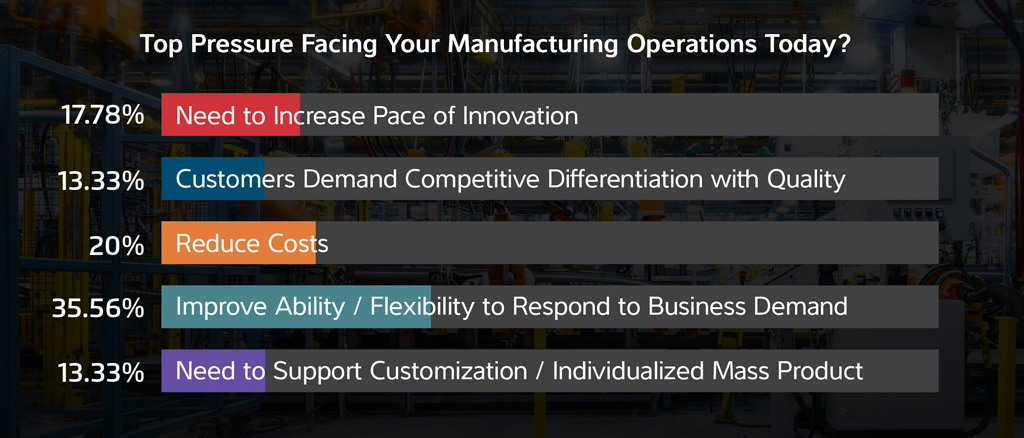

Today's manufacturers are under a lot of pressure. At a high level, they are faced with generating more complex products faster and at a lower cost. The most prevalent forces influencing this demand are the increasing pace of innovation and a hyper-competitive environment. Consumers expect the most complex, high-quality products available today, and if manufacturers can't deliver against that demand, they risk losing their customer base.

During Aegis' recent 'Manufacturing Digitalization Demystified' webinar, attendees were asked in a live poll to identify the top pressures facing their manufacturing operations today. The majority (35.56%) said that improving the ability to respond to business demands was the top pressure. This result is no surprise, as the manufacturing landscape is changing daily, with more supply chain constraints, customer requests, and evolving digital initiatives.

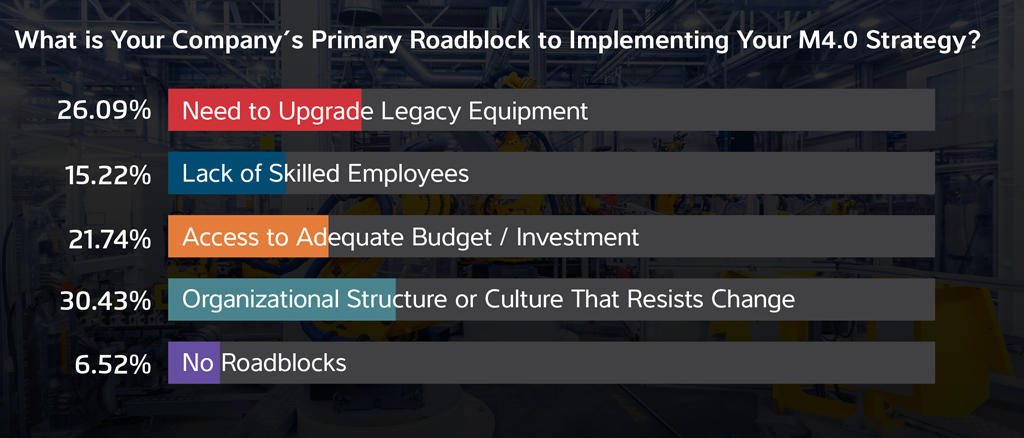

Most organizations want to improve their digital initiatives and advance their Industry 4.0 / Manufacturing 4.0 strategy. However, many are finding this is easier said than done. Gartner's research shows that manufacturers' ambitions toward automated processes align with the ongoing interest in smart factories, but not all processes will evolve in the same fashion. Although it's no surprise that the manual, human-driven processes will decrease over the next five years, digitizing or innovating simple or manual task orientation to a more sophisticated, dynamic process isn't necessarily black and white.

When asked during the manufacturing digitalization webinar to identify their company's primary roadblock to implementing a Manufacturing 4.0 strategy, 30.43% of attendees cited an organizational culture that resists change, and 26.09% said there is a pressing need to upgrade legacy equipment. Certainly, outdated ideas and equipment will hold an organization back in embracing Industry 4.0.

Let's revisit the Rubik's Cube metaphor with three key takeaways from the puzzle that can help manufacturers as they move through their digitalization journey:

Lesson 1: Enable Agility & Resilience without Complexity

Like a Rubik's Cube, the less complexity and uncertainty around the platform and process, the better the chance of solving the puzzle. Enabling on-demand agility and resilience through the right solution—without complexity or the need for custom coding—is crucial for manufacturers looking to streamline workflows and boost efficiency.

Top manufacturing performers recognize the importance of agility to keep a pulse on the market to predict demand, fuel innovation, quickly adjust operational processes, and proactively respond to changing market needs. Those who are falling flat with revenue, missing the mark, or lagging behind the rest are still in the process of transforming their business, and they have yet to implement critical capabilities to support agility. With the right MES/Manufacturing Operations Management (MOM) in place, agility is simple. Organizations can simplify, error-proof, and expedite the operator experience, ensuring the visibility and control needed—all through a connected platform that's truly comprehensive, on a single database, and offers a wide breadth of coverage.

Lesson 2: Reshape the Front Line & Empower Workers

The person solving the Rubik's Cube should have the skills. So too should manufacturing workers, who must be given the right tools and opportunities to level up their skillsets to maintain much-needed efficiency and productivity. It's vitally important for organizations to empower their frontline workers with the right resources to ensure ongoing safety, quality, and success.

Digitization in factories is intensifying today while operational know-how fades. Lower staffing levels, staggered shifts, adjustments to working remotely, and social distancing have all accelerated the integration of the manufacturing workforce with the virtual and physical worlds. Reshaping the front line is as much a technology initiative as it is an exercise in workforce development, behavioral shifts, and integrated continuous improvement.

Lesson 3: Identify Gaps through Manufacturing Intelligence

Like the step-by-step process used to solve the Rubik's Cube, manufacturers should perform a checklist audit to identify gaps and opportunities in their current operations. Manufacturers have more data at their fingertips than ever before—but just collecting that data from the factory floor isn't enough. Manufacturers need to confidently leverage this data for smarter decision-making.

Continuous data collection, especially IIoT data, provides companies with a detailed view of exactly what is happening in the factory and when—ultimately improving the accuracy of predictive models and enabling workers to anticipate changes better. Additionally, integrating disparate data sources into a single, unified, and contextualized platform reduces manual errors and time spent reconciling data to determine which data source is most up to date. This manufacturing intelligence provides organizations with visibility, insights, and the ability to make real-time changes, significantly improving efficiencies and reducing downtime.

Puzzle Solved: Digitalization of Manufacturing Processes is Possible with the Right Solution

The Rubik's Cube of manufacturing digitization can indeed be solved. With the right lessons taken from the puzzle-solving process, manufacturers can align all the moving pieces in the right areas to create a full picture of a complete—and solved—Industry 4.0-enabled factory.

Aegis' FactoryLogix is a holistic and modular platform that enables manufacturers to solve their own Rubik's Cube puzzle and enhance their digitalization efforts. The IIoT-enabled platform is effortlessly configurable and extensible, offering superior visibility and maximum control over every area of your factory.

Watch the 'Manufacturing Digitalization Demystified: Solving the Rubik's Cube of Manufacturing Digitalization' on-demand webinar to learn more.

Sign up for our blog

Stay up-to-date on the latest in manufacturing trends, insights and best practices.